BSRM set to launch new $108m steel plant this month, targeting 34% market share

Infographic: TBS

“>

Infographic: TBS

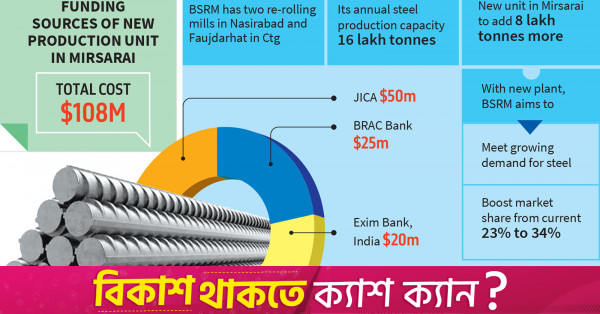

Leading steel manufacturer BSRM is gearing up to launch its $108 million new plant in Chattogram’s Mirsarai by late June or early July. With an annual production capacity of 8 lakh tonnes, this facility aims to raise the company’s share in the local steel market to 34% from 23% now and cater to rising demands for steel products.

“The construction of the new plant on 20 acres of land in Mirsarai is nearing completion. We want to start trial production by late June or early July, followed by full commercial production within a month,” said Tapan Sengupta, deputy managing director of BSRM.

He also told TBS that the new factory is expected to create employment opportunities for approximately 1,000 individuals.

To set up the new re-rolling plant, BSRM secured $50 million in low-cost loans from the Japan International Cooperation Agency (Jica), making it Bangladesh’s first private sector recipient under the Japanese agency’s green industrialisation initiatives.

With the new plant fully operational, boosting BSRM’s total production capacity to 24 lakh tonnes, the steel giant hopes to command more than a third of the country’s steel market.

According to BSRM, the total cost of the new factory construction project is estimated at $108 million (equivalent to Tk1,188 crore). Out of this amount, Jica lent $50 million, with the loan to be repaid over 12 years. The loan agreement was signed on 4 October last year.

Additionally, India’s Export-Import Bank (Exim) has provided a $20 million loan for 12 years; Standard Chartered Bank of Singapore has given $13 million for seven years; and BRAC Bank has loaned $25 million for seven years. All of this credit was given in foreign currency.

Additionally, Prime Bank, Eastern Bank, City Bank, and Infrastructure Development Company Limited (Idcol) extended local currency financing to augment the production capacity of one of BSRM’s melting plants in Mirsarai.

The Bangladesh Steel Re-Rolling Mills Limited (BSRM) and BSRM Steels Limited, both publicly listed, manufacture steel products and raw steel billets.

Currently, the group operates two re-rolling factories in the Nasirabad Industrial Area and Faujdarhat – with a combined production capacity of 16 lakh tonnes of steel annually. The new unit in Mirsarai is also a rolling mill.

In addition, it has four melting factories – two in Chattogram’s Nasirabad industrial area and two in Mirsarai which, with recent upgrades, can produce 24 lakh tonnes of billets, a raw material for steel production, annually.

In addition to producing steel products, the new factory will also manufacture steel wires.

“Currently, we have to import 85,000 tonnes of steel wires annually for our steel wire industry. To reduce this dependence on imports, the new factory is designed to produce 150,000 tonnes of wire steel,” DMD Tapan Sengupta said.

Jica promoting green industrialisation

Jica has traditionally provided loans to the government for large-scale projects like the MRT and Matarbari deep sea port. However, in a landmark move, the Japanese aid agency extended loans to BSRM Steel Limited, primarily to support the green factory initiative.

In a statement following the loan agreement last year, Jica said emissions of environmental pollutants and greenhouse gases from steel plants are a significant challenge. This loan aims to help address that issue.

According to BSRM’s corporate booklet, as part of their commitment to the environment, BSRM factories have achieved zero emissions by implementing Japanese Air Pollution Control (APC) systems across all their facilities.

Additionally, BSRM has generated value from dust collection, exporting dust worth $22.6 million since 2015. They have also invested in advanced European Water Treatment Plants (WTP) for their factories, which recycle 373,700 cubic metres of used water with zero wastage.

Furthermore, BSRM converts 120,000 tonnes of slag waste generated annually at their steel plant into eco-friendly construction material as an alternative to bricks. For this initiative, BSRM received the “SDG Brand Champion Awards 2023”.

“We use recycled water in our factories, meaning zero wastage. All our factories are equipped with Air Pollution Control (APC) systems,” Tapan Sengupta said.

“Plans are in place to fulfil the factories’ power needs through solar energy. Approximately 10MW of solar power will be installed in phases for the steel factories,” he added.

Over the years, BSRM steel products have been chosen solely for building major national landmarks and infrastructures such as the Padma Bridge, Rooppur Nuclear Power Plant, Hatirjheel project, Zillur Rahman Flyover, Mayor Hanif Flyover and Shah Amanat Bridge were built with BSRM, according to the company website.

The company has a history spanning 72 years, starting with its first steel factory, “East Bengal Steel Re-Rolling Mills,” established in 1952. Following Bangladesh’s independence in 1971, it was renamed Bangladesh Steel Re-rolling Mills (BSRM), marking the beginning of its expanded business operations.

According to the company, in the fiscal 2022-23, it generated revenue of $1.691 billion from the sale of 1,777,670 tonnes of steel products. Currently, BSRM provides direct employment to around 5,000 individuals and indirect employment to about 25,000 others.

According to the Bangladesh Steel Manufacturers Association, the country has 55 steel re-rolling mills along with over 100 semi-automatic and manual mills, collectively producing 70-75 lakh tonnes of steel annually. Approximately 50-55 lakh tonnes of this steel is consumed domestically, with the remainder being exported overseas.

Of the total steel consumed within the country, 60% is utilised for implementing government infrastructure projects while the rest is used in the private sector.